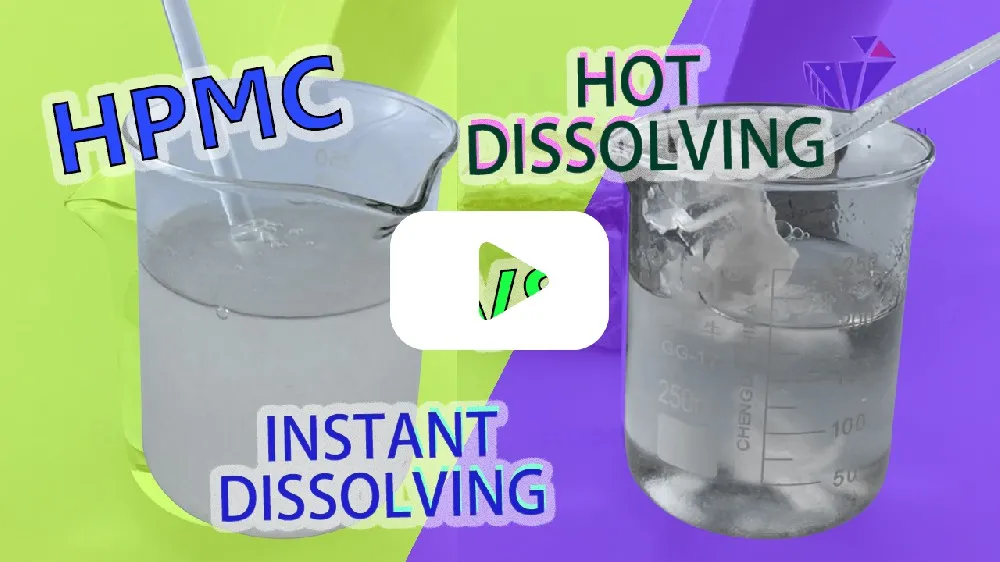

In the realm of food production, HPMC is widely employed as a thickener, emulsifier, and stabilizer. Its unique properties allow it to enhance the texture and consistency of various food products such as sauces, dressings, and baked goods. HPMC not only improves the mouthfeel of these products but also extends their shelf life by preventing ingredient separation and maintaining moisture. Furthermore, it offers a suitable option for gluten-free formulations, enabling those with dietary restrictions to enjoy a variety of foods without compromising on quality.

use of hydroxypropyl methylcellulose